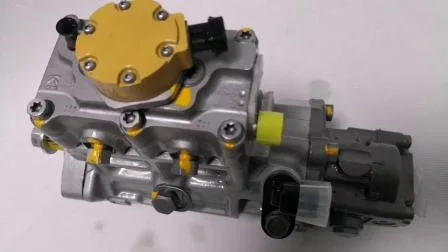

Diesel Common Rail Test Bench Injector Test Equipment Common Rail Injector Tester EPS816f/816g

Overview Package Size 143.00cm * 98.00cm * 168.00cm Package Gross Weight 460.000kg Product Description Function introduc

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | EPS816F/816G |

| Certification | CE, ISO, RoHS, GS |

| Update Method | by Internet |

| Condition | New |

| Standard | Standard |

| Motor | 5.5kw |

| Voltage | Single Phase 220V/3phase 380V |

| Color | Request |

| Transport Package | Plywood Case |

| Specification | 145*170*100cm |

| Trademark | NANT |

| Origin | China |

| HS Code | 9031200090 |

| Production Capacity | 30set /Month |

Packaging & Delivery

Package Size 143.00cm * 98.00cm * 168.00cm Package Gross Weight 460.000kgProduct Description

Product Description

Function introduction:

*Automatically test various solenoid valve injector and piezo injector *Automatically test the performance of injector solenoid valve *Generate IMA code for Bo·sch*Set injection current curve ,injection time and pressure. Fully automatic test of different types of solenoid valve injector and piezoelectric injector*Test the current of injector solenoid valve, valve assembly lift, fuel injection lift.*High pressure cleaning: high pressure cleaning impurities attached to internal parts of injector.*Atomization test: to judge whether the injector is blocked through the atomization effect.*Single injection: the operator can set the number of injections to conduct a single injection observation.*Sealing test: check the sealing performance of nozzle, nozzle cap nut and solenoid valve.*Injector test: Test the injected fuel & return volume under rating, idling, Emission, pre-injection and pre-injection 2 status.*Check, save, print data and customer information.Main configuration:*Equip original Bo·sch CP1 pump*Stainless steel fuel tank with industrial air conditioner to control temperature 40± 2 ºC circularly.*High precision flow sensor.*Equip original Bos·ch DRV, pressure sensor (0-2600bar).* Include DRV, fuel injection cooling treatment device* Include Oil circuit emptying treatment device*You can set the injection current curve by yourselves*The system includes original fuel injector current curve and data*Main motor power 5.5KW, optional three phases 380V 50HZ, three phases 220V 60HZ, two phases 220V/60Hz in convenient for the different need of power supply in different countries. System advantage:*Industrial computer system: Full automatic operation, high speed operation and stable performance.*Original Bo·sch test bench database. Test accuracy similar with the world-leading test bench.*Powerful database: include more than 1,000 kinds of Bo·sch, De·lphi, Den·so, Siemens injector plan, and test plan could be updated free of charge*The operator can choose to test step by step or continuous test*The operator can set injection time and injection pressure during testing*The operator can choose testing results automatically judged by computer system or judge it by yourself.*Injector database management: edit,save, revise and delete*Include Chinese, English, German, Spanish, French, Russian and Portuguese operating interface, which is proper for global using all around the world. *Database remote one click upgradecommon rail injector test bench EPS816G

Function introduction:1. Automatically test various solenoid valve injector and piezo injector2. Automatically test the performance of injector solenoid valve3. Set injection current curve ,injection time and pressure. Fully automatic test of different types of solenoid valve injectorand piezoelectric injector4. Test the current of injector solenoid valve, valve assembly lift, fuel injection lift.5. High pressure cleaning: high pressure cleaning impurities attached to internal parts of injector.6. Atomization test: to judge whether the injector is blocked through the atomization effect.7. Single injection: the operator can set the number of injections to conduct a single injection observation.8. Sealing test: check the sealing performance of nozzle, nozzle cap nut and solenoid valve.9. Injection test: Test the injected fuel & return volume under rating, idling, Emission, pre-injection and pre-injection 2status.10. Check, save, print data and customer information.Main configuration:1. Equip original Bosch CP3S3 pump2. Iron fuel tank with industrial air conditioner to control temperature 40± 2 ºC circularly.3. Includes Germany High precision flow sensor.4. Equip original Bosch DRV, pressure sensor (0-2300bar).5. Include DRV, fuel injection cooling treatment device6. Include Oil circuit emptying treatment device7. You can set the injection current curve by yourselves8. The system includes original fuel injector current curve and data9. Main motor power 5.5KW, optional three phases 380V 50HZ, three phases 220V 60HZ, two phases 220V/60Hz in convenient for the different need of power supply in different countries.System advantage:1. Industrial computer system: Full automatic operation, high speed operation and stable performance.2. Original Bosch test bench database. Test accuracy similar with the world-leading test bench.3. Powerful database: include more than 3,000 kinds of Bosch, Delphi, Denso, SiemensCummins Caterpillar injector plan, and test plan could be updated free of charge4. The operator can choose to test step by step or continuous test5. The operator can set injection time and injection pressure during testing6. The operator can choose testing results automatically judged by computer system or judge it by yourself.7. Injector database (test plan) management: edit,save, revise and delete8. Include Chinese, English, German, Spanish, French, Russian and Portuguese operating interface, which is proper for global using all around the world.9. Database (test plan) remote one click upgrade10. Include common rail injector BIP (injection response time)11. Include CR injector coding creation freely.Optional function1. Support customized products and application.2. Four injectors can be testedat the same time

After Sales Service

Packaging & Shipping

Company Profile

Nanyang Nantai Test Equipments Co.,Ltd is a joint-stock enterprise that produces common rail test bench, common rail injector test bench and diesel injection pump test benches and diesel parts to serve the automobile aftermarket all over the world.Nanyang Nantai Test Equipments Co.,Ltd was established in 1998, and started to fight and create in mechanical pump test bench manufacturing factory. We using the purchasing, machining and sale as our major sales model and laid the foundation for the preliminary development of our company.

FAQ

Q: ARE YOU TRADING COMPANY OR MANUFACTURER ?

A: We are test bench assembling factory. We have had test bench for 20 years

Q: HOW LONG IS YOUR DELIVERY TIME?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity

Q: WHAT IS YOUR TERMS OF PAYMENT ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 40% T/T in advance ,balance before shippment

Q: How about the use of maintenance technology and equipment ?

A:We have free training about test bench,injector and pump maintenance

Q: Why should I choose your product?

A: We can provide you the best quality and the most competitive price ,and we have our own engineer, if you have any requirementsyou can contact us directly.

Related Products

-

![Auto Sensor ABS Sensor Egt Sensor Exhaust Gas Temperature Sensor Nox Sensor Crankshaft Position Sensor Camshaft Position Sensor for Fo Rd Re Nault Op EL Vo Lvo]()

Auto Sensor ABS Sensor Egt Sensor Exhaust Gas Temperature Sensor Nox Sensor Crankshaft Position Sensor Camshaft Position Sensor for Fo Rd Re Nault Op EL Vo Lvo

-

![Gaoxinsens Auto Parts Nitrogen Oxygen Sensor Nox Sensor for Volvo]()

Gaoxinsens Auto Parts Nitrogen Oxygen Sensor Nox Sensor for Volvo

-

![Brand New Nox Sensor for Doc Treatment Control 5wk9 6786]()

Brand New Nox Sensor for Doc Treatment Control 5wk9 6786

-

![Scv Valves 294200]()

Scv Valves 294200